Inhaltsverzeichnis

As a sanitary, vertical conveyor belt system, it’s ideal for food, pharmaceutical, chemical industries, and all sanitary environments as it carries out a wide range of applications. The belt technology is built for steep and vertical inclines, as well as bulk material handling, food process, and as a washdown conveyor, is easy to clean. As its name implies, an inclined belt conveyor operates at an angle, which allows it to transfer product from one level of a store or warehouse to another. The system’s angle can range anywhere from about 18 degrees to an impressive 90 degrees with the right cleated belt.

What is high angle belt conveyor?

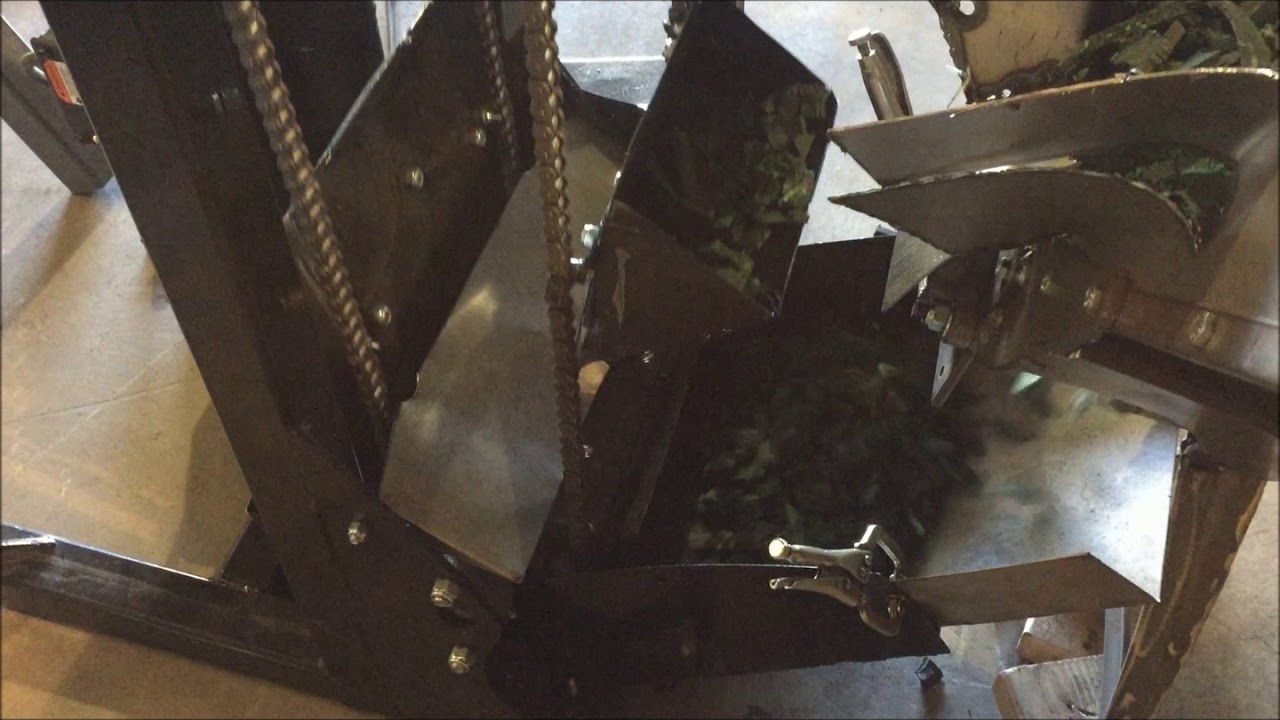

High Angle Conveyor has proven itself to be a versatile and economic method for lifting and lowering material at different angles. The Conveyor can be used at all angle upto 90 degrees as well. With the use of flexowall belting ensures the material is well protected and does not spill.

This unit is also used to convey large volumes of bulk products like wet sludge or sand. As other factors such as transfer points and fugitive material come into play, bulk solids handling experts such as those at FEECO International are often helpful in selecting the most beneficial solution. Pocket or sidewall belting forms “pockets” or troughs at intervals along the conveyor in order to contain material at steep angles. The conveyors meet many different food standard safety requirements and are easy to wipe down and sanitize. AquaGard Conveyorsare constructed with a stainless steel frame and ideal for a variety of applications in packaging and food handling . It features a patented side roller chain to reduce corner friction, allowing faster speeds and smooth product handling.

Manual Heavy Loading Modular Belt Conveyor

Z conveyor belts can be constructed from a variety of plastic link style or ThermoDrive solid surface belting. Incline and steep incline conveyors both offer a reliable handling solution for bulk solids. The decision on which conveyor suits a given job best may require the help of a bulk solids handling expert. And while steep incline conveyors cannot utilize the belt cleaners that standard incline conveyors can, enclosures are available to minimize fugitive material. Belt thumpers, which shake material off the belt, are also available for steep inclines.

- For these reasons,based on the industry needs, iConvey specially develop modular belt incline conveyors.

- It can be configured with different inclination angles and speeds in order to adapt to the characteristics of any warehouse.

- Also, a incline conveyor won’t offer you any benefit if it is outside your budget.

- The products are wedged between opposing conveyors, aligned either vertically or horizontally, and moved quickly and safely.

This internal transport system ensures the continuous flow of unit loads to the storage, production, or dispatch zone. Moreover, incline conveyors are a scalable, versatile, and configurable solution. A typical incline conveyor is simply a troughed belt conveyor positioned on an incline (or decline). Troughed belt conveyors are generally not effective at inclines greater than 18 degrees, as material slippage on the belt becomes a major concern. Conversely, steep incline conveyors can convey material at inclines up to 90°. Manufacturers have developed various types of conveyor belt systems to serve a wider variety of operations.

Conveyor Frame

Another one of our company’s many success stories featuring automatic incline conveyors is C.D.A.L, a distributor of spare car parts for wholesalers. For this facility, the Mecalux Group designed a box conveyor line fully adapted to the layout of the warehouse. The conveyor moves prepared orders from the storage area on the upper level to the consolidation and dispatch zone on the ground floor.

One of our expert consultants will advise you on the best solution for your company. It’s important to recognize that neither type of conveyor is necessarily better than the other; whether or not one is a fit over the other is dependent on the specific parameters of the situation. Wedge Conveyors are lightweight, easy to add to floor layouts, and have a quick transfer rate. It passes strict hygiene standards needed for medical and cosmetic packaging. Applicable for lift-conveying of granular products such as potato chips, candies, nuts, frozen food, vegetables, chemical medicine, etc.

What is conveyor belt types?

They are used to transport materials from one point to another, often over long distances. Conveyor belts can be made from a variety of materials, including PVC, polyester, cotton, and rubber. There are four main types of conveyor belts: flat belts, modular belts, timing belts, and V-belts.

Incline Belt Conveyors or Floor to Floor Conveyors transport product between elevations. As the name suggests, they are often used to carry product to and from a mezzanine or between floors in a warehouse. Low-profile belt hold-downs allow this unit to fit into https://sepmachinery.com/bucket-elevator/ tighter spaces than large wheel hold-downs.

We are specialists in pallet racking, picking shelves, automated warehouses and logistics software. The chart above illustrates the distance/length requirement for the level of incline on an inclined conveyor. The FlexMove Helix is a compact spiral and helical curve, flexible chain, conveyor. The unique and flexible design can be customized as needed to different heights and angles depending on needs. The 2200 Series conveyors are best for small to medium part handling, transfers, positioning, and automated and manual assembly. Mecalux has an extensive catalogue of technology solutions that greatly boost the throughput of logistics operations.

AquaPruf VBT(Vertical Belt Technology) is used for elevating bulk products like vegetables and fruits, popcorn, grains and nuts, pet food, pharmaceuticals, and small packages. Endless cleat height and spacing options to ensure optimum product conveyance. Modular frame and curve sections give multiple configuration options, as well as, economical changes.

Our incline conveyors can come equipped with horizontal sections, infeed, and/or outfeed to provide better product handling and controls. Mk incline conveyors are also ideal in hopper applications or feeding parts into bowl feeders. Automatic belt conveyors are an ideal solution for transferring products between a mezzanine or upper level to the ground floor of the warehouse or the other way around.

Warehouses use incline conveyors to bridge gaps in a facility in a safe and agile way. This is the case of audio equipment distributor Algam, which relied on the Mecalux Group to automate its order consolidation area with box conveyors. The operational differences in these two types of conveyors necessitate different physical and structural requirements for each type as well. These differences are most apparent in the conveyor belting and the structural framing.

This reduced capacity is because the sidewalls on the steep incline belt take up a portion of the belt width, making the “effective width,” or the width inside the sidewalls, slightly less. While both offer an effective handling solution, these two conveyor types operate and are designed very differently, making the selection between the two dependent on a few key factors. In an effort to make the choice between the two more clear, we’ve outlined the primary differentiators between incline conveyors and steep incline conveyors here.

Sanitary Z Conveyors

Incline conveyors and decline conveyors offer safe product flow and control while optimizing for speed and efficiency, depending on the space available. You can customize your incline conveyor belt with a belt that has grips, barriers, or other features designed to keep products in place. You can rest assured that your materials will make it to their destination safely.

Conveyors are internal transport elements that, on top, contain sets of rollers or belts to move goods in a continuous and controlled way. Product weight, size, surface material and belt type need to be considered when planing a floor to floor installation. Incline conveyors require a specific amount of conveyor length to reach the desired amount of lift (see chart below). In other words, if a steep incline conveyor is not used, the greater the amount of lift, the longer the conveyor will need to be in order to convey the material at an angle that promotes optimal handling.